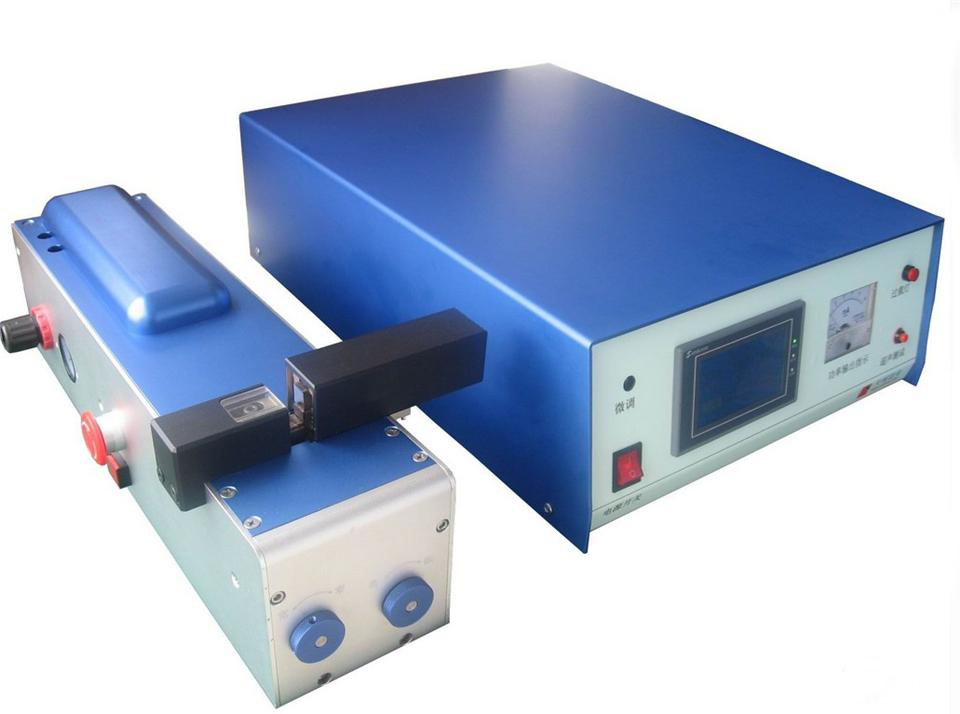

Precision Wire Harness Splicing Machine

- Brand:

- JW

- Transportation:

- Ocean,Air

- Place of Origin:

- China

Product Description

Ultrasonic Metal Spot Welder

Ultrasonic metal welding machine product features

◆ With the latest IC control technology, it can provide time, power, pressure, welding depth and other welding modes

◆ Suitable for welding applications with very high requirements for process control and welding quality

◆ The whole series is equipped with ZT first SG series digital ultrasonic generator, full function MPS4 controller and newly designed press, which can adapt to more applications of various products, with higher welding quality and smoother and faster welding process

◆ It can be used in manual, semi-automatic or fully automatic production environment. The power output can be customized according to the model: 1500W to 7500W

No load, no load resonance, no need to adjust welding head

◆ Servo control is adopted to adjust the welding height. The all-digital control unit is input by touch screen, and the welding precision can be adjusted up to 0.01mm and the time accurate up to 0.1ms

◆ There is no need to preheat the product, you can choose different welding surface mold lines

◆ Good electrical conductivity after welding, very low or near zero resistance coefficient, short welding time, do not need any flux, gas, solder

Applicable to ultrasonic metal welding machine:

Applicable industry: new energy, battery, solar energy, military industry, aerospace, glasses, power motor, super capacitor, etc

◆ Suitable for: copper, aluminum, stainless steel, nickel, gold, silver and other non-steel materials

◆ Suitable products such as: battery connector terminal solar energy

Nickel metal hydride battery nickel mesh and nickel sheet intermelt

◆ For lithium battery and polymer battery, copper foil is interfused with nickel sheet, aluminum foil is interfused with aluminum sheet, copper foil is interfused with nickel sheet (negative electrode), aluminum foil is interfused with aluminum sheet (positive electrode), aluminum and nickel, aluminum-Nickel composite strip, cover plate and cap

◆ Wire intermelting, partial to one and multiple intermelting

◆ Wire and various electronic components, contacts, connectors interfusion: patch thick film resistance, PATCH inductance, relay, electromagnetic switch, fusible switch, connector, diode lead: electrolytic capacitor pole ear, transformer

◆ Large heat dissipation seat, heat exchange fin, honeycomb core melting of various household appliances and locomotive supplies

◆ Electromagnetic switch, no fuse switch and other large current contacts, intermelting of heterogeneous metal pieces

◆ Sealing and cutting off of metal pipe can be water and air tight

◆ Auto parts: airbag Wire Harness, collector ring, filament, lamp cover.

Applicable to: copper, aluminum, red copper, aluminum, nickel, gold, silver and other non-steel materials

Applicable industry: new energy, battery, solar energy, military industry, aerospace, glasses, power motor, super capacitor, etc

Applicable products such as: battery connector terminal solar power cell electronic components

Nickel metal hydride battery Nickel metal hydride battery nickel mesh and nickel sheet intermelt

Copper foil of lithium battery and polymer battery is interfused with nickel sheet, aluminum foil is interfused with aluminum sheet, copper foil and nickel sheet (negative electrode), aluminum foil and aluminum sheet (positive electrode), aluminum and nickel, aluminum-Nickel composite strip, cover plate and cap

Wire melting, skewing into a and a number of mutual melting

Wire and various electronic components, contacts, connectors interfusion: patch thick film resistance, PATCH inductance, relay, electromagnetic switch, fusible switch, connector, diode lead: electrolytic capacitor pole ear, transformer

A variety of electrical appliances, locomotive supplies large cooling seat, heat exchange fin, honeycomb core melting

Electromagnetic switch, no fuse switch and other large current contacts, intermelting of heterogeneous metal pieces

Sealing tail of metal pipe, cutting off water and air tight.

Specific applications of ultrasonic metal welding machine are as follows:

Welding of strands of stranded wire to rows of wires

Welding of rotor and rectifier

Welding of rare metal electrical joints

Welding of large wire and terminal

Welding of copper terminal and beryllium copper alloy

Electromagnetic wire terminal welding

Brush braided copper wire for welding with main power cable

Polymetallic wire end weld

Welding of multiple stranded wires to terminals

Welding of contact components

Welding of stranded copper wire and beryllium copper terminal

Engine outlet ends welded

Welding of wire terminal and forming terminal

Welding of thick copper sheet to aluminum sheet

Welding the braid terminal to the engine brush

Connect the batteries by welding

Welding of nickel plated lead to platinum lead of thermoresistor

Small metal sheet and metal mesh, metal foil welding

Welding of solid copper conductor to brass terminal

Welding copper braid to brass terminal

Welding of brush holder assembly

Product Categories : Ultrasonic Metal Welding Machine > Ultrasonic Metal Welding Machine